Chicken Farming Processing: A Comprehensive Look From Farm to Plate

Chicken Farming Processing is one of the most popular meats globally, prized for its versatility, affordability and taste. But the journey from a fluffy chick to the neatly packaged chicken breasts you see at the supermarket is a complex one. This article delves into the world of chicken farming and processing, exploring each step in detail and offering insights into the benefits, goals, and considerations involved.

Chicken Farming Processing

The chicken we consume goes through several distinct stages before reaching our plates. Here’s a simplified breakdown:

- Breeding: Specialized breeder flocks produce hatching eggs.

- Hatchery: Eggs are incubated under controlled conditions to hatch chicks.

- Broiler Farm: Chicks are raised in large houses for several weeks until they reach slaughter weight.

- Processing Plant: Chickens are slaughtered, defeathered, eviscerated (internal organs removed), and cleaned.

- Further Processing (Optional): Chickens may be cut into parts, deboned, or marinated for specific products.

- Distribution and Retail: Processed chicken is shipped to supermarkets and butcher shops for consumers to purchase.

Benefits of Chicken Farming Processing

- Affordability: Chicken is a relatively inexpensive source of protein compared to other meats, making it accessible to a wider range of consumers.

- Nutritional Value: Chicken is rich in protein, low in fat (depending on the cut), and a good source of essential vitamins and minerals.

- Versatility: Chicken can be prepared in countless ways, making it a staple in many cuisines around the world.

- Efficiency: Modern chicken farming and processing are highly efficient, producing a large amount of meat with minimal resource use.

- Economic Impact: The chicken industry provides significant employment opportunities in rural communities and contributes to the agricultural sector’s overall economic well-being.

Goals of Chicken Farming Processing

The primary goals of Chicken Farming Processing are:

- Produce high-quality, safe chicken meat for consumers. This involves maintaining strict hygiene standards throughout the process and ensuring proper handling and storage to prevent contamination.

- Maximize efficiency and profitability. Producers strive to raise healthy chickens quickly and efficiently, while processors aim to minimize waste and maximize output.

- Meet consumer demand for affordable and convenient chicken products. This includes offering a variety of cuts and products to cater to different preferences and cooking styles.

- Minimize environmental impact. Sustainable practices are becoming increasingly important, with efforts to reduce waste, water usage, and greenhouse gas emissions.

The Art and Science of Chicken Farming Processing

Raising chickens for meat production requires a balance of art and science. Here’s a closer look at the key aspects:

- Breeds: Different breeds are chosen for specific purposes. Broiler chickens, for example, are bred for rapid growth and meat production.

- Chick Management: Chicks require a carefully controlled environment with proper temperature, ventilation, and lighting to ensure their health and well-being.

- Feed and Nutrition: Chickens are fed a balanced diet formulated to meet their nutritional needs for optimal growth and development.

- Biosecurity: Strict biosecurity measures are implemented to prevent the introduction and spread of diseases within the flock. This includes vaccinations, hygiene protocols, and controlling access to the farm.

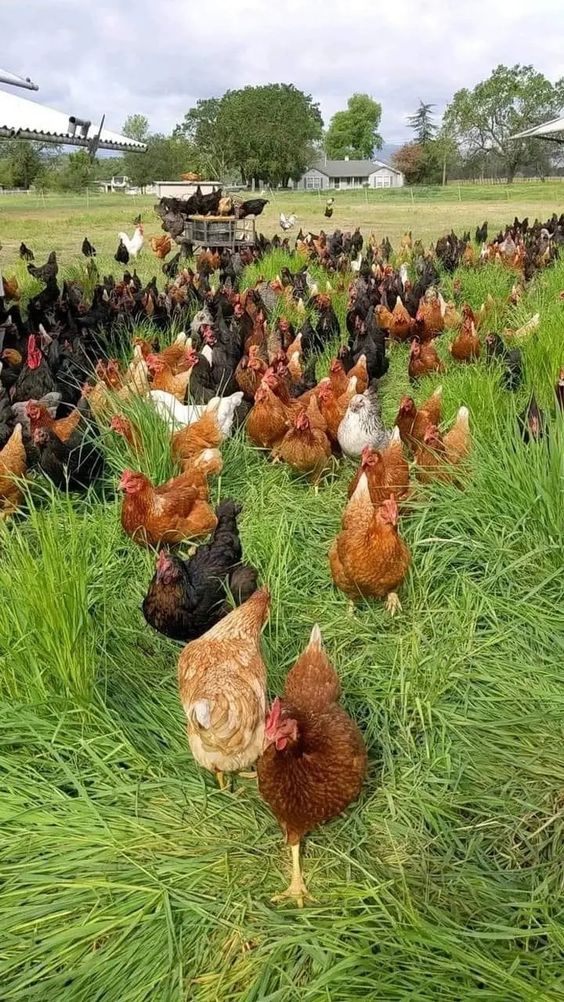

- Animal Welfare: There’s growing emphasis on ensuring the welfare of chickens throughout their lives. This includes providing them with adequate space, enrichment activities, and humane handling practices.

Chicken Farming Processing Plants: Efficiency and Safety

Chicken Farming Processing plants are marvels of modern technology, designed to handle large volumes of birds efficiently and safely. The process typically involves the following steps:

- Stunning: Chickens are rendered unconscious using electrical current or controlled atmosphere stunning to minimize pain and stress.

- Slaughtering: Chickens are killed humanely, following strict regulations.

- Scalding and Plucking: Hot water loosens feathers, which are then removed mechanically.

- Evisceration: The internal organs are carefully removed by automated machinery or skilled workers.

- Cleaning and Chilling: The chickens are thoroughly cleaned with chlorinated water to remove contaminants and then chilled to prevent bacterial growth.

- Grading and Inspection: Chickens are graded based on size and quality and inspected by government officials to ensure they meet safety standards

Further Processing: From Whole Chicken to Chicken Nuggets

While some chickens are sold whole, many undergo further processing to create a variety of convenient and popular products. This stage may involve:

- Cutting: Chickens are cut into various parts like breasts, thighs, wings, and drumsticks.

- Deboning: Bones are removed mechanically or by hand to create boneless chicken breasts or thighs.

- Marinating: Chickens are soaked in marinades for added flavor and tenderness before cooking.

- Chicken nuggets and tenders: Bite-sized pieces of chicken, often breaded or battered, popular for their ease of preparation.

- Ground chicken: Lean ground chicken is a versatile ingredient for burgers, meatballs, and sausage.

- Chicken sausage: Seasoned and formed chicken meat, available in various flavors and styles.

- Pre-cooked chicken: Roasted, grilled, or flavored chicken pieces ready to heat and eat.

- Diced chicken: Pre-cut chicken pieces for quick and easy stir-fries or salads.

- Chicken hot dogs: Made from processed chicken meat, offering a lower-fat alternative to traditional hot dogs.

Considerations and Challenges Chicken Farming Processing

Chicken Farming Processing face several ongoing challenges:

- Balancing Efficiency and Animal Welfare: There’s a constant push to find ways to improve efficiency while ensuring the humane treatment of chickens. This includes providing them with more space, natural light, and enrichment activities.

- Antibiotic Use: The overuse of antibiotics in chicken farming can contribute to antibiotic resistance in humans. Producers are exploring alternative methods to prevent and control diseases.

- Food Safety Concerns: Strict regulations and hygiene protocols are essential to prevent contamination throughout the processing chain.

- Environmental Impact: Large-scale chicken production can generate waste and contribute to greenhouse gas emissions. Sustainable practices like using manure as fertilizer and reducing energy consumption are becoming increasingly important.

- Consumer Preferences: Consumers are becoming more interested in where their food comes from and how it’s produced. Transparency and ethical sourcing are becoming key factors influencing purchasing decisions.